By Krithika Shekar and Ruella Menezes

Methanol’s versatility makes it an attractive option for today’s energy challenges. One of its key advantages is its ability to remain liquid at ambient temperatures and pressures, simplifying storage, transport, and distribution. Moreover, methanol can easily integrate into existing fuel infrastructure and blend with conventional fuels, minimizing the need for extensive system changes.

This adaptability, along with its environmental benefits, positions methanol as a compelling solution for future energy production. These unique properties have brought methanol back into focus, with 30% of its current consumption directed towards fuels.

Today, Methanol stands as a key contender for meeting the world’s growing energy needs. It is a clean-burning, cost-effective fuel that is widely available. In particular, renewable methanol is emerging as a promising player in the transition to a sustainable, low-carbon economy. As governments globally implement regulations to lower greenhouse gas emissions and reduce dependency on fossil fuels, renewable methanol has gained traction as a viable fuel alternative.

In this blog we touch upon the different applications of renewable methanol and highlight the innovative efforts of companies leading this transformative journey.

What is Renewable Methanol?

Renewable methanol is a sustainable alternative to traditional methanol, produced using renewable energy and feedstocks through two primary methods:

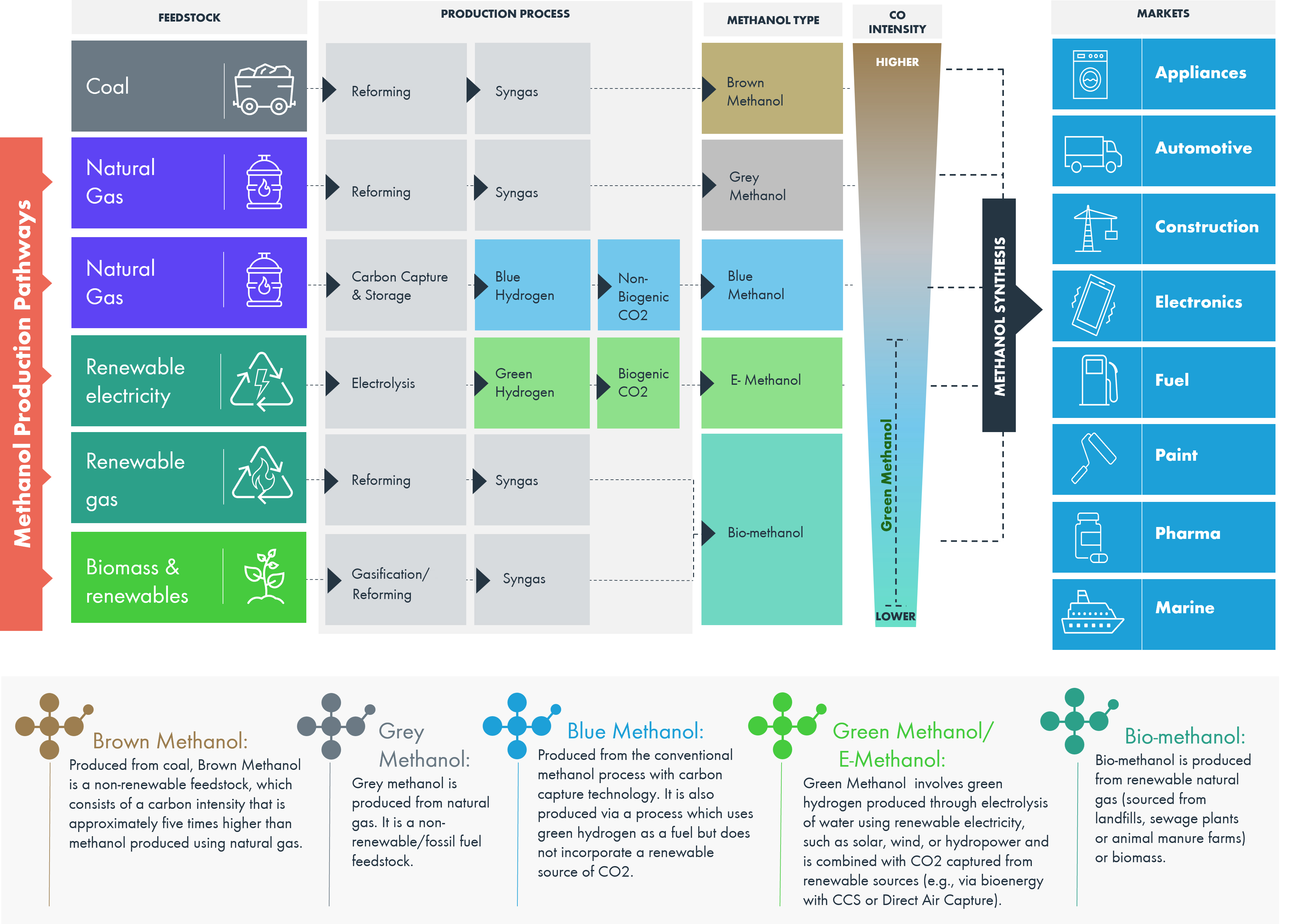

- Bio-methanol: Bio-methanol from renewable natural gas (sourced from landfills, sewage plants or animal manure farms) or biomass. Potential sustainable biomass feedstocks include but are not limited to (i) forestry and agricultural waste/byproducts, (ii) municipal solid waste and (iii) black liquor from the pulp and paper industry.

- E-methanol or Green Methanol: Green hydrogen (i.e., hydrogen produced with renewable electricity) is combined with CO2 captured from renewable sources (e.g. via bio-energy with CCS or Direct Air Capture).

Today, almost 99% of Methanol is produced from natural gas and coal (particularly in China) (Figure 1.0). The cost of production is influenced by the availability and cost of raw materials, including coal and natural gas, freight costs, other operating and maintenance costs and government policies. Currently, less than 0.2 Mt of renewable methanol is produced annually, predominantly as bio-methanol. Despite the different production methods, renewable methanol is chemically identical to fossil fuel-based methanol.

Figure 1.0 Renewable Methanol types and applications

The Case for Methanol as an Alternative Fuel

The case for methanol as a fuel began in the 1970s and 1980s when it emerged as an alternative to crude oil-based fuels during oil supply constraints. With its high-octane rating, methanol was tested extensively in the 1980s and 1990s, both as a low-blend component and a pure fuel to reduce air pollution. Its low production cost from coal and natural gas, and compatibility with existing vehicle infrastructure, made it an attractive option. However, by the late 1990s, advancements like direct fuel injection and three-way catalytic converters addressed emission issues in gasoline-powered vehicles, reducing the benefits of methanol-based fuels. Consequently, despite its technical success, methanol did not achieve commercial success due to low oil prices.

Methanol is once again garnering attention as a versatile option for marine fuel, vehicle fuel and as a fuel for industrial boilers, kilns and cooking stoves. The demand for Methanol as a fuel is expected to grow over the coming years with several emerging and potential new applications. The section below explains why.

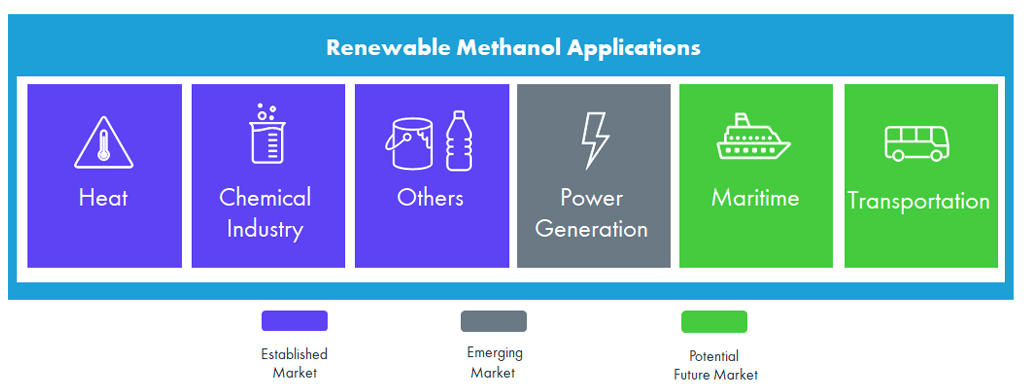

The Methanol Potential: Established vs Emerging:

Chemical:

Today, traditional chemical demand accounts for roughly 50% of global methanol consumption and is primarily used in the production of chemical derivatives such as formaldehyde, acetic acid, and a wide array of other chemicals. These derivatives serve as the foundation for numerous industrial and consumer products, underscoring methanol’s essential role in the chemical industry.

Heat:

Renewable methanol, having significantly lower air emissions (NOx, SOx, and PM), is finding use as a fuel for thermal applications such as industrial boilers, kilns, heating furnaces and as a cooking fuel. The growth in demand for methanol as a fuel for heating purposes comes from China, where industrial boilers are used extensively to generate heat and steam for various industrial applications and kilns. The country is adopting stricter environmental regulations, prompting the transition to cleaner burning fuels including methanol.

A research study conducted in 2023, carried out by China Association of Alcohol and Ether Clean Fuel and Automobiles indicated that about 60% of China’s use of methanol as energy (excluding MTBE and MTO) is as cooking fuel.

Transportation Fuel:

Renewable methanol is increasingly being used as a clean and efficient transportation fuel. It can be blended with gasoline or used as a standalone fuel in internal combustion engines.

China is at the forefront of methanol fuel adoption, utilizing methanol in blends from 5 percent to 100 percent (‘M5′ to ‘M100′) to promote fully methanol-powered vehicles. Currently, around 30,000 taxis and methanol hybrid passenger cars, as well as 4,000 heavy-duty trucks, operate on M100 fuel in China, amounting to an annual demand of roughly one million tonnes of methanol. An extension of China’s faith in methanol is seen where the Chinese owned company Geely Sichuan Commercial Vehicles, launched an e-methanol powered truck in collaboration with Circle K in Europe. The tank can contain up to 800 litres of methanol to accommodate the long distances driven by trucks. Since 2022, the truck has been in operation at the Port area of Aalborg.

Maritime Fuel:

Maritime transport has also shown significant interest in methanol as a marine fuel. This interest is driven by methanol’s environmental benefits, wide availability, cost competitiveness, and ease of use. The demand for methanol as a marine fuel is on the rise, evidenced by increasing orders for dual-fuelled vessels and retrofits. As of February 2024, DNV reported there are 29 methanol-fuelled vessels already in operation while 228 vessels are on order indicating a significant rise in the number of methanol-fuelled vessels. Most of these vessels are in the container ship segment.

Several major shipping companies are leading the way in this transition. Maersk, Mitsui O.S.K Lines, CMA CGM, and Nippon Yusen Kabushiki Kaisha (NYK) are either already deploying methanol-fuelled dual fuel vessels or have plans to develop them in the near future. Notably, Maersk has made headlines by signing a substantial green methanol offtake agreement with Chinese developer Goldwind. This agreement marks the first large-scale green methanol offtake in the shipping industry, setting a significant precedent for the future of maritime transport.

Power Applications:

Methanol for power generation offers utilities fuel flexibility, for example, power plants operating on diesel can switch to methanol thereby operating on either fuel which mitigates the risk of fuel-price volatility. Furthermore, the focus of countries globally to align with environmental regulations, as well as improve overall air quality, is encouraging the transition to renewable methanol for power generation.

A case in point is Israel, where a decade ago the country switched to methanol with the aim of complying with environmental regulations and their clean air requirements at the lowest possible cost. In line with this, the Israel Electric Company invested approximately US$5 million to convert a 50MW Pratt & Whitney turbine at a power plant in Eilat, to run on methanol. The switch proved to be successful and helped in reducing emissions (100% emission reduction of Sulphur Oxides, 75% reduction in emission of Nitrogen Oxide and 80% Particulate Matter reduction).

Additional applications for the use of renewable methanol include construction, paint and pharma industries; it is also suitable for use in Direct Methanol Fuel Cells (DMFCs) and Reformed Methanol Fuel Cells (RMFCs), providing a clean and efficient source of electricity. DMFCs are ideal for portable and small-scale applications, while RMFCs are used for large-scale stationary power generation. For example, SerEnergy, a Danish company specializing in methanol fuel cell technology, has developed systems that use renewable methanol to generate electricity. Their fuel cells are deployed in off-grid power solutions, backup power systems, and as range extenders for electric vehicles. Renewable methanol holds significant promise as a sustainable and versatile energy source. Its potential to reduce greenhouse gas emissions, coupled with its diverse applications and compatibility with existing infrastructure, makes it an attractive alternative to fossil fuels. However, addressing challenges such as high production costs, limited capacity, energy intensity, policy barriers, and market acceptance is crucial for its widespread adoption.

As technology advances and economies of scale are achieved, the cost of producing renewable methanol is expected to decrease, making it more competitive with conventional fuels. Supportive policies and regulatory frameworks will play a vital role in fostering the growth of the renewable methanol industry. By overcoming these challenges, renewable methanol can become a cornerstone of the global transition to a sustainable, low-carbon future.

This blog is one in a series of articles from Kline’s Green Value Compass (GVC), examining the value of alternative fuel and energy sources. For more information click here.